Here’s another opportunity to learn for free a lesson that has already cost someone else.

Recently I learned that a utility in our program incurred a major claim when a roofer was electrocuted following contact with the connection between their wires and the home’s service drop. As it happened, the tape used to cover and insulate the connection had deteriorated in the decades since it was installed, such that when the man working on the roof touched it he was electrocuted, and died before falling to the ground.

I know it may seem like a fatality in these circumstances is unlikely, but it happened! Even worse, it was the second claim for contact with an uninsulated weatherhead connection within a 3 year span. This is a significant concern, not just for the utility involved, but for every member of this program. As a result, it is worth considering how such an event can come to pass and find some steps that can be taken to prevent such a mishap at your utility.

We all realize that time and weather will wear down almost anything. Witness the Grand Canyon, where water has worn down rock to produce that iconic national landmark. Given that demonstration of power, what chance does a bit of electrical tape stand when wind, rain, sleet and snow have ready opportunities to do their worst against it?

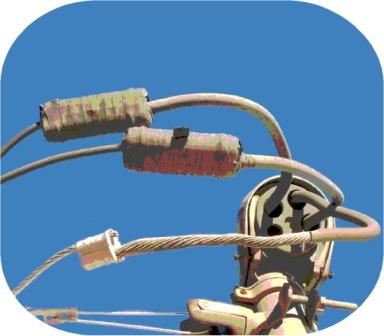

Nearly every electrical code holds the customer responsible for providing a safe and solid service drop, or weatherhead, for the distribution company to attach to. Similarly, utilities are required to make this connection and secure it. Today there are a variety of means to make this connection, from compression clamps to insulated crimp sleeves to clamps that are fully covered by insulated “boxes” that snap closed. (Even old split bolt connections can still be found on older installations.)

Regardless of what type of connection is used, most folks tell me that they routinely tape the connector for security, even the boxes, which can pop open if the latch is stressed too much. Unfortunately, as we all know, even the best electrical tape applications will eventually deteriorate and fail. This is exactly what caused the distribution system that sparked the idea for this article to end up with their problems.

A further complication that may be compounding the problem is the growing use of automatic meter reading systems that allow for remote access to usage data. In the old days, when I first got involved in power distribution, it was common for a utility to have an employee meter reader go out monthly to every customer’s residence or business take a meter reading. In the course of this work, the meter reader was expected to cast an experienced eye over all of the connections and devices on the outside of the structure, including the meter itself, the mast, connections, and service wires tracing back to the transformer on the pole. But times changed, starting with the use of outside contractors for meter reading and then to electronic devices that allowed for “drive by” readings, and now to full-on AMRS and Smart Meters that don’t require that anyone ever go to see the actual meter, although usually an annual check and reconciliation may be done. As a result, the “experienced eye” is infrequently, even rarely, able to see conditions at the users’ sites.

All of this adds up to a significant potential problem, since the failure to find and repair defects on the lines will inevitably lead to service issues, to after hours “on call” overtime costs, and perhaps to significant claims for damage and even injuries like those described above. There are two major steps that can be taken to reduce the chances of things going wrong with these service drop connections. The first is to take a proactive interest in finding the best technical solution for your area. Take a look at all of the options available for making and protecting these connections, select the one you believe best meets the requirements of your situation (which vary by climate and construction type) and then train your staff on how to use the device effectively. The second is to add the inspection of these connections to the standard form used in your regular line patrol efforts. You will have to allow more time for these inspections, even require inspectors to (Oh the horror!) get out of their vehicles and look closely at older connections to spot poor tape conditions, and then you will have to decide if you want to invest in replacing these with your newest connectors or (at the least) just provide a short term solution by re-taping them. As the saying tells us, “You can pay a little now, or pay a lot more later.”

All of this adds up to a significant potential problem, since the failure to find and repair defects on the lines will inevitably lead to service issues, to after hours “on call” overtime costs, and perhaps to significant claims for damage and even injuries like those described above. There are two major steps that can be taken to reduce the chances of things going wrong with these service drop connections. The first is to take a proactive interest in finding the best technical solution for your area. Take a look at all of the options available for making and protecting these connections, select the one you believe best meets the requirements of your situation (which vary by climate and construction type) and then train your staff on how to use the device effectively. The second is to add the inspection of these connections to the standard form used in your regular line patrol efforts. You will have to allow more time for these inspections, even require inspectors to (Oh the horror!) get out of their vehicles and look closely at older connections to spot poor tape conditions, and then you will have to decide if you want to invest in replacing these with your newest connectors or (at the least) just provide a short term solution by re-taping them. As the saying tells us, “You can pay a little now, or pay a lot more later.”