Preventive maintenance may appear to be a somewhat dull and mundane topic that everyone is all too well aware of, one that has been thoroughly discussed many times, a basic element of every power system, so what could be left to say on this subject that is new or interesting? Well, please don’t skip this article, since there are some valuable insights to be found by looking at events taking place regularly, in various areas across the country.

In the past year this program has seen a notable uptick in the number of line contacts, both BI and PD incidents, some admittedly more troubling than others, of which most if not all of which could have been prevented had more attention been devoted to basic preventive maintenance efforts.

All of you know that Synebar’s consultation visits include questions about pole inspections, ROW maintenance, and line patrol. Most co-op safety leaders recognize the importance of each of these efforts in the effort to keep the power flowing safely to the membership. But let’s dig a little deeper into the implications of each of these programs to see if we can find a new perspective on the importance of each one.

Pole inspections are reasonably well understood by nearly all our clients these days, perhaps in part due to the frequent discussions held about them. It is common for a safety officer to ask, “How frequently do we have to test our poles?” That’s a simple question with a complicated answer. Synebar’s typical response is to say that you should test frequently enough to meet your minimum acceptable failure rate goal. But that answer may raise as many questions as it answers. Let’s pull it apart, beginning with the idea of a “goal.” All that means in this context is, “What reject rate poles, or failure when tested, are we will to accept from the system’s poles?” This is commonly expressed as a percentage of the total, as in a 3% failure rate, which means that of every 100 poles tested, 3 are reported as “bad” or “suspect” with regard to their condition. Your utility may have a higher or lower target, depending on the nature of the area served and leadership’s tolerance for risk. Lower failure rates imply fewer unexpected failures, less unplanned or after-hours repair work, and higher costs of testing. Higher failure rates, unsurprisingly, predict the reverse. We find, however, that most utility safety officers want to know specifically how often to conduct tests, and they find our answer difficult use to get that number. But how often to test is simply not that difficult to figure out, once you have a goal. If your current testing protocol is returning failure rates higher than the goal, more frequent testing is needed, while if pole reject rates are lower than the goal, frequencies can be reduced. In either case, having a goal is the key. Given the multitude of variations from place to place that have to be accounted for — wind, weather, terrain, system age, pole type — it is impossible to prescribe a specific number of years between inspections that will apply to all cases.

Despite these challenges, the RUS has made some effort to guide the process with RUS BULLETIN 1730B-121, updated most recently in 2013. It is intended “To furnish information and guidance in establishing a continuing program of pole maintenance.”

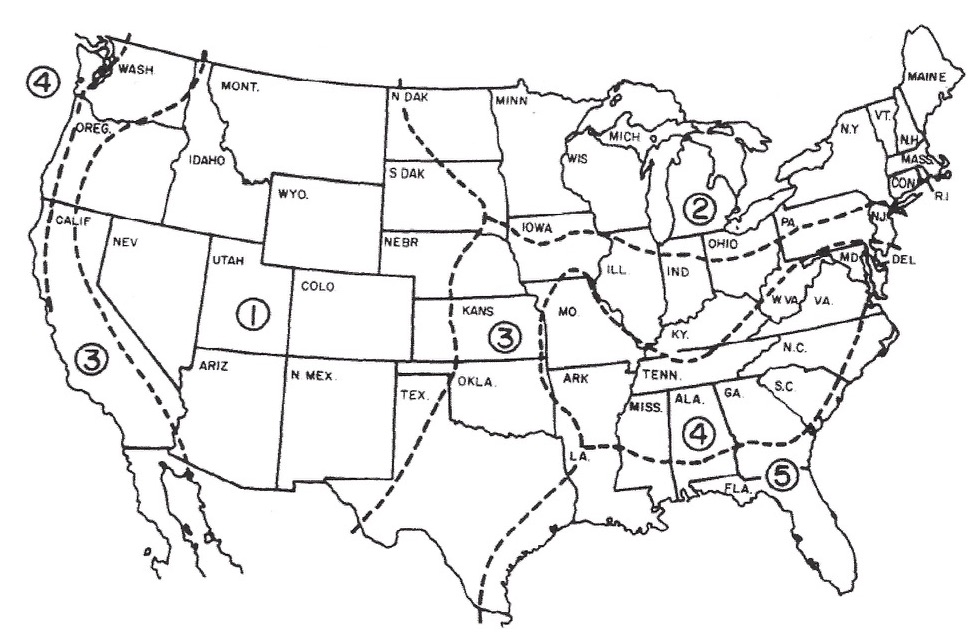

The bulletin includes a map of the USA with 5 indicated “decay severity zones” and with 3 suggested pole inspection groups. (Zone One is Inspection Group 1, while they have merged zones Two & Three and zones Four & Five as Inspection Group 2 and Inspection Group 3 respectively.)

Decay severity zones for wood utility poles as defined by the USDA Rural Utilities Service. Decay is least severe in zone 1, most severe in zone 5.

[Editor’s Note: This map is very rudimentary, with the appearance of having been drawn on a cocktail napkin sometime in the 1950’s, and is therefore difficult to use for a utility with a territory on or near a “zone line.”]

The Bulletin states that:

The suggested timing for initial pole-by-pole inspection and subsequent re-inspection, when supplementary treatment is applied after each inspection, is as follows:

| Decay Zone | 1 | 2 & 3 | 4 & 5 |

| Initial Inspection | 12-15 years | 10-12 years | 8-10 years |

| Subsequent Inspections | 12 years | 10 years | 8 years |

| Percent Poles Inspected | 8.3 | 10 | 12.5 |

NOTE: The full bulletin with the map and inspection groups (on pages 5 & 6 of the document) can be found at the flowing URL, https://www.rd.usda.gov/files/UEP_Bulletin_1730B-121.pdf

Key to the effectiveness of any pole inspection effort is to have trained inspectors, either in-house staff or contractors. Each approach has advantages and drawbacks. The results seem to favor the use of contractors, who are specialists in this work with well trained staffs. (This does not describe all contractors, so caveat emptor, Latin for buyer beware!) In-house inspectors are often less well trained, particularly in smaller companies, and less available for regular, planned inspection efforts.

In sum, the most important part of any pole inspection program is setting a reject rate goal. A sampling of poles will give you an idea of how your current program is working relative to the goal. Adjust your inspection frequency until the results match the target goal. If you don’t have a documented plan, at least meet the RUS Guidelines.

ROW clearing is the second element of this 3-pronged preventive maintenance program. All of the comments on pole inspections relative to variability are true here too, and even more so, in ROW clearing. Not only does the need for clearing vary from utility to utility, it also varies, sometimes tremendously, within a single utility system. Some areas have little or no vegetation, or are highly developed with few trees, while others are forested, thick with foliage. Growth rates also vary, from hardwood trees to soft pines or other fast growing plants. Some utilities are in areas so arid or rocky that the local joke is that any trees have names and are treated as pets, while utilities in wet or mountainous areas are often so thickly forested that ROW clearing is a constant headache. Each company will have to calculate its own needed frequency of clearing, type of approach, and areas to target, based on the local climate and conditions. One leading indicator is your outage history, which will show you where in your system the ROW needs the most attention. Sampling too will assist you, just as in the pole testing discussion above. Other things to consider is the local acceptance of clear cutting the ROW, any bans or limitations on the use of chemical herbicides or grown inhibitors, and restrictions on ROW clearing on public lands.

ROW clearing is so varied from area to area, and even within a utility, that it is nearly a fools errand to make any generalizations about the “best” or recommended frequency. The primary need is to decide on what rate of ROW work will lead to the level of system failure that is within your leadership’s tolerance. As I often note, it is always cheaper to do work that is planned, in the course of regular work hours, than it is to do work in an emergency, after hours situation. Dollars spent to find and fix defects before they caused incidents will cut the costs of emergency work. With that said, most of our clients will not exceed a 5-year cycle, with high growth areas getting more frequent clearing. As with the pole testing, ROW work can be successfully done either in-house or with contractors. The deciding factors are usually the need to control the work on the one hand and the need to invest in expensive machinery on the other. From an insurance perspective, if the contractors are well chosen and carefully instructed, this approach may help you avoid some of the financial costs of trimming errors.

Line patrol is the third element of the program, the one that is the least well understood and most variably practiced. Our outlook is that an organized program of line patrol (a careful visual inspection of the lines, guys, grounds, and attachments) is a crucial element of an effective preventive maintenance effort. Yet, we frequently find that it is the least emphasized, or too ofter the most neglected, element of the prevention programs. So, let’s start with a look at what too many utilities still use as a line patrol program.

Many times safety contacts say that they have no full-time inspectors, and do not contract for this work, but instead they expect everyone to look at the lines in the course of their daily duties and to fix or report any defects that they spot. This is best understood as an “old time, by-the-way, inspection program.” I don’t mean to be dismissive of this approach, in that it is a decent way to find and fix open and obvious defects on the lines, primarily in areas visible from the roads traveled by the line workers in the course of their regular work. Unfortunately, it has some very significant gaps in effectiveness. For one, it means that lines near the main warehouse are seen nearly every day by nearly everyone, while distant lines are much less often looked at, and cross country lines are almost never viewed by any worker driving along. Secondly, many workers are alone in their vehicles, and can hardly be expected to give their attention to both the road and the lines they are driving past, never mind their other distractions like the radio, their directions, and their phones. Yes, they will spot issues like a broken or badly sagging line, guy wire, or cross arm. But they will not necessarily spot a clearance issue, code inadequacy, ground problem, or attachment issue. They will certainly not see any lines going cross country, or across bodies of water. And perhaps most importantly, it is nearly impossible for anyone to manage this type of inspection effort, since typically the only documentation of the work is a work ticket or staking sheet created after a problem is seen. Put your finger on a random spot on your line map and ask yourself this question, “How would I answer the question of when this place was last patrolled?” Then think about how hard it would be to answer that question for every mile of line. In short, absent a formal, organized effort to go look at the lines, it is nearly impossible for anyone to properly manage an inspection program.

Some readers may be thinking about the difficulty of designing a better inspection program. All I can say is that in some areas the PUCO requires all utilities to conduct an annual visual inspection of their lines. Surely you can do this every few years. There are a variety of alternatives to having a full-time inspector, although many utilities do choose that option. As an alternative, some of our clients set aside a couple of weeks every year for a stand down, during which all field workers do nothing but inspect lines. Others ask their servicemen to conduct detailed visual inspections of the lines in their assigned territories on a regular basis, and document them so that managers can tell where, when, and by whom the inspections were done, allowing for them to adjust the work based on the results they see. Even asking line workers to use paper maps and highlighters to show each week’s work would make it possible to identify areas that haven’t been visited in some time that should be assigned for special attention.

Line patrol is a critical way to find out where circumstances have changed out in the system. Construction of buildings, billboards, marquees and signs, new driveways, road paving, parking lot paving (reducing clearances?), land usage and clearing, especially around pole bases, are all simple examples of things that occur all the time, often without any notice to you as the utility. If you have lakes or other navigable waterways, you need to check on their use, including boat ramps and launch areas, as well as looking at clearances and codes where lines cross waterways, things that are typically not going to be seen unless specifically searched out.

In summation, keeping the lines up and the power flowing is the basic description of the work of a distribution utility. The public expects power, thinks you should keep the wires and poles up, and not cause any hazards for them. It may be a nearly impossible task, given the fact that materials wear and fail, wind and weather will occur, including some severe conditions. Nevertheless, you should do your best to minimize the frequency of failures, and prevention is the most effective way to limit losses. I urge you to give careful thought to how well (or not) your utility performs these three basic preventive programs of pole testing, ROW clearing, and line patrol.